To provide high functional materials

to next generation nano-device

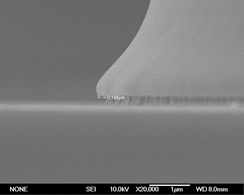

Negative Photoresist

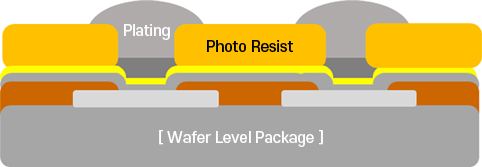

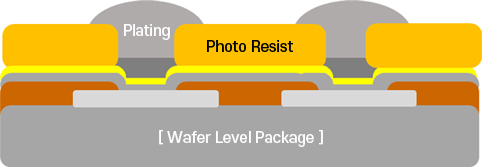

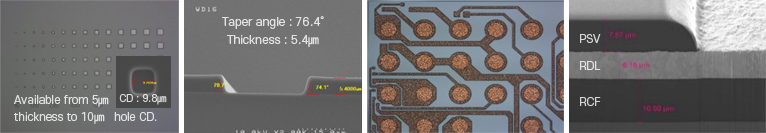

Negative Thick photoresist for Wafer Level Package - RDL, CPB

-

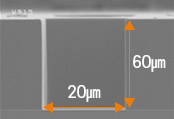

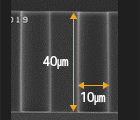

Cu RDL (Redistribution Layer)

- PR pattern

- Cu RDL

-

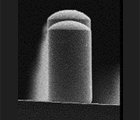

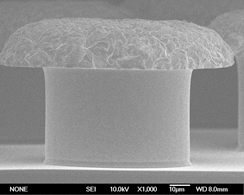

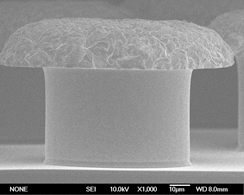

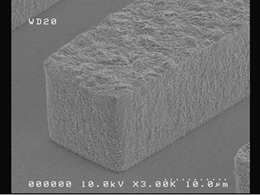

CPB (Cu Pillar Bump)

- PR pattern

- CPB

- Securing polymer and formulation design technology

- Excellent pattern profile (no footing, no under-cut)

- Excellent process margin

- Fast processing

- High resolution

- High plating resistance

Positive Photoresist

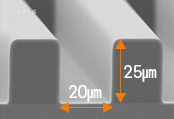

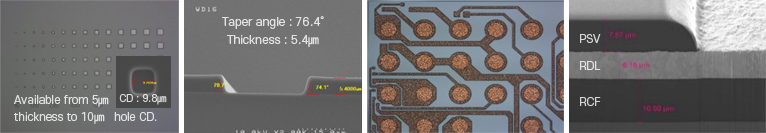

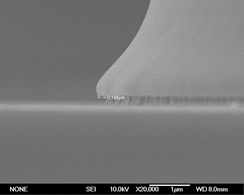

Positive Thick photoresist for TSV, CPB

-

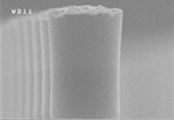

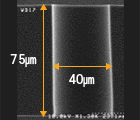

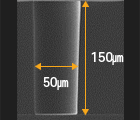

TSV (Trough Silicon Via)

- PR pattern

- Plating

-

CPB (Cu Pillar Bump)

- PR pattern

- Plating

-

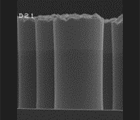

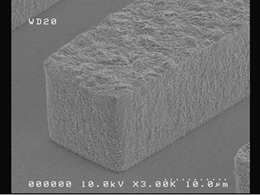

Tall Pillar

- PR pattern

- Our own polymer design and optimized Formulation

- Excellent pattern profile (no footing, no under-cut)

- Excellent strip ability (no residue)

- High resolution / aspect ratio

- Wide process margin

- Excellent chemical & plating resistance

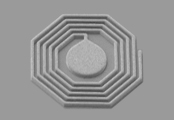

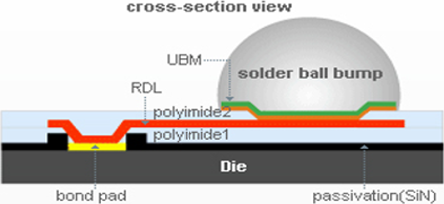

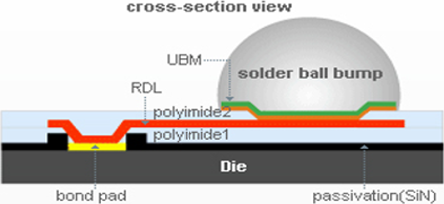

Photo-definable Dielectiric

Photo-definable dielectric for advanced package

- NDP-Series used as various protection/insulation layers in the bumping process

- Soluble Polyimide backbone: Ultra-low-temperature cure, ultra-low shrinkage

PR Stripper

- It is possible to remove the thick photoresist without metal damage and residue

- An aqueous or organic type stripper can be selected according to the photo process conditions

- Low Metal Damage (Cu, Ni, Sn, Ag, Al)

- Strip performnce can be controlled according to the type of PR and thickness.

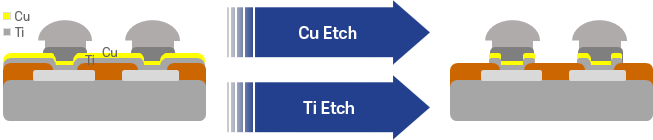

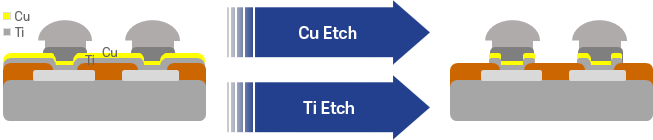

Cu / Ti Etchant

Cu Etchant

- Excellent etching uniformity and selective etch rates

- Wide-range etch control (30Å/s~200Å/sec)

- Low Metal Damage (Ag, Sn, Ni, EP-Cu)

Ti Etchant

- Excellent selective etching of Ti, Ti/W with non-fluoride series

- Etch rate control by H₂O₂ mixing ratio is possible (5 ~ 22Å/sec)

Au Etchant

- Excellent etching uniformity of Au (gold) metal with iodine based etchant

- Low Metal Damage (Al)

- Securing excellent material safety Excellent etching uniformity Exellent Number of throughput & Bath Lifetime