Look to the Future through the highly advanced

technology and science of nepes.

HYPER CONNECTING TECHNOLOGY

nepes creates Hyper-connecting technologies to lead future businesses.

-

Semiconductor

PLP / FOWLP / WLP solution

Bumping, FOW-SiP / Test Service

-

Artificial Intelligence

Predictive Maintenance

Vision Inspection / etc

-

IT Materials

Process chemicals

Functional chemicals

-

Rechargeable Battery

Lead Tab(ESS, Automotive)

LIB anode electrode

-

Energy

Green Construction

Smart window / Low-E film / Smart Film

New

Global

Leader

-

Stock Information KOSDAQ

033640.KQReal-time stock info

-

Year of Establishment 1990

The path taken by nepes, the "eternal life," over the past 30 years. The management philosophy of nepes is volunteering life, willing attitude, and grateful heart.

-

Sales 4,800

Thanks to steady growth each year, nepes recorded sales of about KRW 418.4 billion in 2019. This year, we promise to take a step forward and show satisfactory output for you.

-

Workers 2,300

Ushering in the future, nepes cultivates professional talents who challenge themselves with passion and vigor and build teamwork based on mutual consideration.

PUBLIC RELATIONS

-

-

Nepes - Inha University Manufacturing Innovation Graduate School Semiconductor Professional Training

On April 29, Nepes signed an agreement with Inha University’s Graduate School of Manufacturing Innovation for cooperation in fostering semiconductor professionals.The signing ceremony was attended by seven people from the semiconductor industry, including Nepes, Hana Micron, SEMCNS, YC, EXICON, DAEDUCK. With this business agreement, Inha University has decided to foster specialized personnel in the semiconductor process intelligence convergence master’s course with government support until 2031 in order to systematically cooperate in fostering personnel, including the full cycle of semiconductor industry intelligence, including fostering new personnel, fostering incumbent R&D personnel, and strengthening practical capabilities, fostering packaging specialists, and specializing personnel in utilizing semiconductor infrastructure.

2025-05-02

-

-

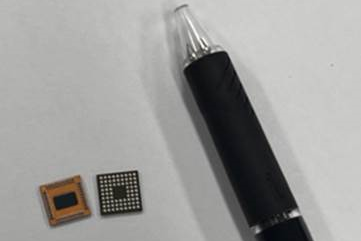

Nepes, Targeting the Popular Edge Computing Market with Advanced Packaging Technology

Nepes, a semiconductor post-processing (OSAT) specialist, is targeting the popular edge computing market with advanced packaging technology based on the fan-out (FO) process. It plans to target the 2.5D packaging and chiplet markets based on technologies such as RDL (re-wiring) interposers and silicon bridges. Kang In-soo, head of Nepes Semiconductor Research Institute (executive director), explained at the ‘Advanced Electronic Assembly Technology and Market Trend Seminar’ held at the Suwon Convention Center on the 2nd, “We are talking about on-device (edge) AI now, but in reality, it seems that the algorithms suitable for it have not yet transitioned to edge computing.” He added, “The inference AI market is expected to grow 10 times larger than the learning market in the future, which means that the AI market that we can enjoy has not yet arrived.” He added, “I think the true AI era will come when we transition to popular edge computing, and we need to prepare for that era.”View original article = 네패스, 첨단 패키징 기술로 보급형 엣지 컴퓨팅 시장 공략- 시사저널e

2025-04-10

-

-

Cheongju City -Nepes, Signing Investment Agreement for Expansion of High-Performance Advanced Semico

Cheongju City announced on the 28th that it signed an investment agreement worth 160 billion won with Chungcheongbuk-do and Nepes, a system semiconductor advanced packaging specialist. The agreement was signed on the 27th.Nepes is a mid-sized company with global competitiveness in the system semiconductor advanced packaging sector. Through this agreement, it plans to invest in expanding production facilities at Ochang Plant 2 in Ochang-eup to respond to the increasing demand for high-performance AI semiconductors.With the expansion, Nepes is expected to establish itself as a global supplier of semiconductor packaging for AI data centers and chiplet (2.5D, 3D)* packaging.*Chiplet: A technology that designs and manufactures a single chip by dividing it into multiple small modular chips. Mainly used to integrate AI semiconductors and HBM (high bandwidth memory) into a single package.Cheongju City will actively support companies to carry out their business stably, and Nepes will actively participate in the development of the local economy by giving priority to local residents for new hires, participating in local construction companies, and purchasing local materials.A city official said, “Through this investment by Nepes, Cheongju’s status as a center for the advanced semiconductor industry will be further solidified,” and “We will not spare any support to ensure that the business is carried out smoothly.”Lee Byeong-gu, CEO of Nepes, said, “We will actively respond to the increasing demand for semiconductors for AI, such as data centers, autonomous driving, and humanoid robots, build a K-semiconductor cluster ecosystem, and achieve greater growth in the global semiconductor market.” He added, “We will also contribute to the revitalization of the local economy by coexisting with the local community.”청주시-㈜네패스, 1600억 ‘투자 협약’…AI 반도체 생산시설 확장 | Save Internet 뉴데일리

2025-03-31

-

-

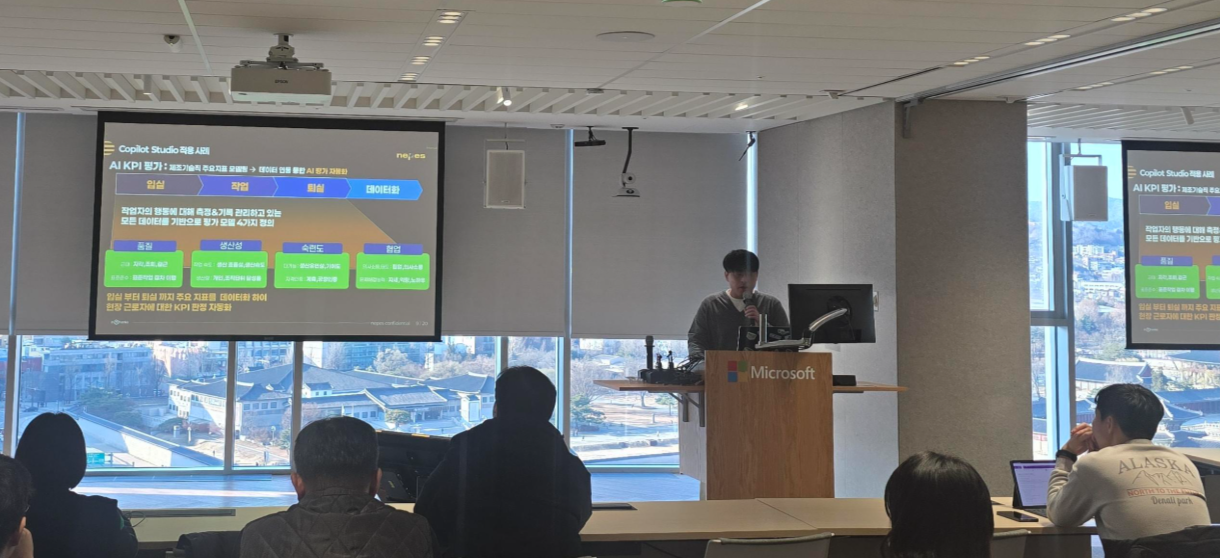

Nepes, strengthens corporate competitiveness with AI innovation strategy

On December 17, Nepes presented the application cases and future direction of Copilot Studio at a seminar held at Microsoft Korea. Part Manager Kwon Hyo-jin (CIO HQ Information System Team), who was in charge of the presentation, shared the company's case of building large-scale data processing and infrastructure through AI Build-Up, securing various types of large-scale data to create a flexible work environment, and said that it is using this to help with quick decision-making by utilizing AI training and personal AI assistants.Nepes introduced M365 Copilot in August and maximized work efficiency by utilizing generative AI functions in various M365 products such as Teams, Outlook, Word, Excel, and PowerPoint. Starting next year, it plans to introduce Copilot plugin and Action Copilot to launch system automatic control AI service. In addition, Nepes introduced HRSM service through HR innovation project to improve the quality of HR service and visualize and improve the efficiency of HR work progress. It improved the evaluation method by establishing an AI KPI evaluation system through data-based evaluation and automation, and increased real-time inquiry response and HR work efficiency by introducing AI Copilot for year-end settlement.In the future, Nepes plans to introduce PBL (Project Based Learning) to secure AI manufacturing competitiveness and operate the Copilot power user training program so that all employees can utilize the AI secretary. Part Manager Kwon emphasized that Nepes will continue to pursue AI innovation and supply and operate a stable system for global business expansion.

2024-12-26

-

![[DIC2024] Nepes Increases Production and Reduces Costs for FO Packaging](https://www.nepes.co.kr/data/bbsData/17461609729.jpg)

-

[DIC2024] Nepes Increases Production and Reduces Costs for FO Packaging

Jong Heon Kim, head of Nepes' Technology Development Division, gives a presentation on 'Trends and Role of Advanced Packaging Technology in High Performance Products' at the '2nd DigitalDaily Industry Conference (DIC) 2024', held from 1:00 p.m. on November 21st at the Yeouido FKI Tower Conference Center Diamond Hall in Seoul, Korea .[DigitalDaily reporter Kim Moon-ki] “Our continued efforts in packaging for the production of semiconductors in the AI era aim to increase production capacity. Nepes strives to bring not only productivity but also price competitiveness through fan-out (FO) packaging technology to silicon interposer. We will provide multiple services on a two-track basis, including technologies that cover 2.5D packaging and hold multiple chips in one package.”Jong Heon Kim spoke about Nepes' competitiveness on the topic of 'Trends and Role of Advanced Packaging Technology in High Performance Products'. “The current semiconductor market resembles a war more than a strategy. As the market gradually localizes, we must focus on our strengths,” Kim said, adding that ”the same is true for the advanced packaging field.”The pressure to follow Moore's Law is on, he notes. The curve of Moore's Law, which requires a doubling of scale every two years, has been bent. It costs around $500 million to design and test an existing chip and $30-40 million to produce a single wafer. Difficulties in manufacturing and prolonged periods of development, along with the high cost are proving to be a challenge. “Packaging is the answer to physical limitations, manufacturing difficulties, and cost reduction,” said Kim. ”If there is a best practice in the construction of existing SoCs, we should follow it. Currently, chiplets are on the rise, as they can be divided by functions, in which simple processes and difficult processes are separated and put back together in the later stage of production."Kim, however, points out that while silicon intensifiers offer high performance and efficiency in 2.5D packaging, they can be costly. An alternative is fan-out (FO) and wafer-level package (WLP) technology, which Nepes focuses on. This technology involves packaging chips on a wafer-by-wafer basis. It is advantageous for cost reduction as it eliminates the need for printed circuit boards (PCBs) and reduces the number of processes.<source=nepes corp.><source=nepes corp.>Kim also emphasized the need to foster the entire cycle of production from Front-end process to Back-end process.“Even if the process is broken down into chiplets and put back together again, chip design and packaging must work together organically," he said. “In other words, it is important to build an ecosystem where the front and back are connected. In the end, the packaging and the chip must be designed together,” he said.“It is said that Korea's competitiveness requires reviewing packaging from its beginning stage. We believe that there is potential and possibility to foster a whole ecosystem of AI semiconductors because we have AI data, foundries, and data-based platform companies," he said, adding, "Korea is also in dire need of technology collaboration." [Source = DigitalDaily [DIC2024] 김종헌 네패스 “FO 패키징 ‘생산증가 원가절감’…韓 디자인-패키징 공급망 강화해야” - 디지털데일리]

2024-11-25

-

-

Nepes Participates in IMSP 2024

Nepes participates in the International Symposium on Microelectronics and Packaging (ISMP), an international conference dedicated to the latest trends in semiconductor packaging technology. The 22nd ISMP, organized by the Korea Society of Microelectronics and Packaging, is held on November 6-8 at the Paradise Hotel in Busan, and is co-hosted with the 18th International Conference Reliability and Stress-Related Phenomena in Nanoelectronics(IRSP).On November 6-7, Nepes will introduce its core technologies, including chiplet and 2.3D technologies, at Lobby Booth 2. On November 6 at 3:50 p.m., Nepes Semiconductor Research Center's Advanced Technology Part Leader Lee Jung Won will present on the topic of “Chip-let Heterogeneous Integration Packaging Based on Fan-out RDL Interposer Technology”.

2024-11-06

-

-

Nepes Holds 34th Founding Anniversary Celebration

Nepes celebrated its 34th founding anniversary on October 24th. Nepes held the ceremony from 8:30 a.m. with a worship service of thanksgiving, a commemorative video screening, a message from the CEO, and a special music class. All employees participated online and offline to share in the celebration. Afterwards, Nepes held various commemorative events such as long-term service awards for each campus, autumn hikes, and a gratitude bazaar.“For 34 years, our company has been able to grow steadfastly in the face of numerous challenges. This is thanks to our shared dreams and visions, and your dedication to doing your best in your respective positions,” said Byung Koo Lee, CEO of the company. “We have the DNA to turn turbulent external environments into opportunities for revitalization,” he said, encouraging employees that "Here at Nepes, we are the superstars who strive to be the ’The First of Yesterday and the Best of Tomorrow'".Lee also said, “To make another 34 years of expectation and excitement into an opportunity to rebound, we must first create synergy by inspiring a sense of mission in what we do. Second, we must fulfill our business plan goals with a sense of responsibility and vocation. Third, we will create an energetic and exciting work environment”.

2024-10-25

-

-

Nepes Kim Jong Heon Lectured advanced semiconductor packaging at 'Nano Korea 2024 Industrialization

▲Kim Jong-heon, Vice President, Lecture at the 2024 Industrialization Session of Nano KoreaNepes gave a lecture on advanced semiconductor packaging technology at 'Nano Korea 2024 Industrialization Session' held at KINTEX 1st exhibition hall in Goyang City on the 4th.Kim Jong-heon, vice president of Nepes CTO, said, "The advanced packaging technology in AI era; Chiplet and Integration ', introduced chiplet and heterogeneous packaging technology, a cutting-edge semiconductor packaging trend.Nano Korea is one of the world's top three nanotechnology events, hosted by the Ministry of Trade, Industry and Energy and the Ministry of Science and ICT, and organized by the Nano Convergence Research Association and the Nanotechnology Research Council. Among them, the industrialization session is a program that domestic and foreign global companies announce in-depth about the direction of their nanotechnology commercialization, and invited nine speakers of next-generation semiconductor and display industries, including Nepes, Samsung Electronics and SK Hynix, to give lectures.Vice President Kim Jong-heon said, "The development of Gen AI is accelerating changes in many fields such as life and industry," and explained, "In the packaging field as well as the entire semiconductor process, AI semiconductor-oriented bumping, 2.5D, and chiplet technologies continue to develop, and Nepes also has and develops related technologies and is pushing for commercialization."He added, "In addition to packaging technology, heat dissipation performance, which is closely related to power consumption, is also becoming important." He emphasized the importance of developing innovative materials along with package structure design.Meanwhile, Nano Korea is a high-tech exhibition that can confirm the commercialization status of nanotechnology and roadmap of famous domestic and foreign companies. 400 companies from 40 countries participated and 12,000 people visited.

2024-07-08

-

-

Nepes Participates in the 2024 ECTC

Nepes participated in the 2024 Electronic Components and Technology Conference (ECTC) in Denver, Colorado, USA from May 28 to 31 (local time) to showcase advanced semiconductor packaging technology.Celebrating its 74th anniversary this year, the 2024 ECTC is an international event hosted by the IEEE-affiliated Electronics Packaging Society and boasts the world's largest electronic component technology society.Nepes presented a 600mm FOPLP solution and a chipset packaging based on a fan-out RDL interposer at the event.On the next day of the event, the technical program participated in the announcement of advanced packaging technology with Samsung Electronics and SK Hynix as Korean companies.Nepes introduced the excellence of FOPLP as a replacement for the traditional package QFN, titled '600mm x 600mm Fan-Out Panel Level Package (FOPLP) as an Alternative to Lead-Frame-Free Quad Flat No Lead (QFN) Package'.In the Interactive Presentations session held on the same day, I also presented my thesis on 'Single and Multi NPU Chiplet Heterogeneous Integration Packaging Based on Fan-Out RDL Interposer with Silicon Bridge Technology'.

2024-06-03

-

-

Nepes pushes for commercialization of AI semiconductor packaging

Nepes has developed next-generation packaging PoP (Package on Package) technology for artificial intelligence (AI) and advanced semiconductor, and is working with domestic and foreign chip manufacturers to commercialize it.Recently, as the AI package market has been struggling with the global supply chain due to the oligopoly of Taiwanese companies, Nepes has developed and commercialized PoP technology, which is the base technology of 2.5D packaging *, utilizing its strengths, RDL technology.* 2.5D packaging: A technique for horizontally matching a semiconductor die on a wide substrate-shaped interposer, which is mainly used to integrate AI semiconductors and HBM (High Bandwidth Memory) into a single package.2.5D packaging, which is being developed by Nepes, has the advantage of price competitiveness and small form factor by implementing a rewiring (RDL) interposer using a fan-out process instead of an expensive silicon (Si) interposer.In particular, the developed PoP technology includes element technologies such as semiconductor device embedding technology, double-sided rewiring (RDL) technology, and Vertical Interconnection. It is a basic platform technology of advanced packaging that can expand its use to smartphone and automobile AP (Application Processor), wearable sensors, and AI semiconductors.Kim Jong-heon, chief executive officer of Nepes CTO, has been awarded "excellent performance by a global semiconductor company in Japan, a manufacturer of LiDAR sensors, which is a core technology for autonomous car, and is in the process of negotiating product applications. We are actively discussing commercialization. And based on the PoP technology developed this time, we will concentrate on 2.5D packaging technology for AI semiconductors and complete development with customers in the first half of 25 years and aim to mass-produce from the second half."Nepes is a strategic market that drives next-generation growth and aims to enter the commercialization of 2.5D and PoP technologies from the second half of 2025 by actively collaborating with AI server, automobile and edge computing product customers.press release inquiry : pr@nepes.co.kr

2024-05-20

-

-

Nepes and Eumseong County Disabled Welfare Center Sign MOU for Disability Welfare Improvement

On March 11, 2025, Nepes (President Lee Jung-young) and the Eumseong County Disabled Welfare Center (Director Jeon Ho-chan) signed a Memorandum of Understanding (MOU) to enhance disability welfare and realize social value. The signing ceremony took place at the Welfare Center's conference room, with key members from both organizations in attendance.President Lee Jung-young emphasized Nepes' commitment to social responsibility and continuous support for improving the quality of life for people with disabilities. Director Jeon Ho-chan expressed gratitude for Nepes' support and pledged to create a warmer welfare environment through collaboration.This MOU is expected to provide substantial support to people with disabilities in Eumseong County and contribute to spreading a culture of sharing in the community.

2025-03-12

-

-

Nepes, Ministry of Gender Equality and Family 'Best Family Friendly Management' Certification

Nepes announced on the 24th that it has received the 'Best Family Friendly Management' certification from the Ministry of Gender Equality and Family.The Best Family Friendly Management certification is a government system that grants companies that operate family-friendly systems in an exemplary manner so that employees can balance work and family life, and was introduced in 2008.Nepes operates various systems to help employees balance work and family life. It is implementing a flexible work system that allows employees to choose their own working hours and a half-day system that allows employees to use their annual leave in units of hours. It also provides support for operating a workplace daycare center, supporting children's tuition and medical expenses, and supporting spouse health checkups.Through this certification, Nepes received excellent evaluations in various categories such as operating a family-friendly system, compliance with related laws, and employee satisfaction, and will maintain its qualification until 2027. If you obtain the family-friendly certification, you can receive additional points and other benefits in various evaluations and support projects by the government or financial institutions.Nepes announced that it plans to continue improving and expanding its family-friendly system to ensure the satisfaction of both employees and their families.

2024-12-24

-

-

Nepes, selected as an excellent workplace for “non-discriminatory workplace”

On the 5th, Nepes was selected as an excellent workplace for non-discriminatory workplace in 2024 at the ‘2024 Excellent Workplace Awards Ceremony for Creating a Workplace without Discrimination’ hosted by the Labor and Management Development Foundation.This awards ceremony, with the theme of a non-discriminatory workplace and a culture of mutual prosperity, selected and awarded 20 excellent workplaces that took the lead in improving employment structure and discrimination against irregular workers.Nepes received the Secretary General’s Award from the Labor and Management Development Foundation for contributing to creating a workplace without discrimination by converting subcontractors to regular employees in 2022.

2024-12-09

-

-

Nepes EM Division, Chuseok holiday food sharing volunteer activity

On September 12, the Nepes EM Division Divide Club, together with the Welfare Center for the Disabled, conducted a social contribution activity to share the holiday food made with the difficult neighbors in the area ahead of Chuseok.About 10 employees of the Eumseong Campus, including members of the Nanumi Club, handcrafted and carefully packed holiday foods at the Eumseong County Welfare Center for the Disabled and delivered them directly to vulnerable families near the workplace.An employee who participated in the volunteer service said, "Everyone was delighted to participate in volunteer activities, thinking of the neighbors who would be delighted to receive the gifts we made." "We hope that our neighbors will have a little help in sending a warm Chuseok holiday."I expressed my participation testimony.

2024-09-13

-

-

Nepes backs travel bags for children from low-income families

On the 29th of last month, Nepes delivered travel bags to 84 low-income families in Cheongju during the summer vacation season.This sharing activity was conducted through collaboration with the Korea Human Resources Development Corporation and the World Vision Lava Welfare Center, and was designed to help children develop their dreams and hopes through various emotional and physical experiences.On the other hand, Nepes continues to sponsor low-income family children in the community to promote welfare by carrying out various sponsorship programs such as the Children's Day Happiness Package Sharing Event and the Foundation Anniversary Scholarship Support. In the upcoming Christmas, we will deliver a gift package containing school supplies and daily necessities.Ko Eun-young, a cultural part, said, "We will continue to look for places where community needs help and spread the culture of sharing."

2024-09-03

-

-

Nepes shares Lunar New Year gift sets with underprivileged neighbors

Nepes corporation practiced warm neighborly love during the Lunar New Year holiday.World Vision 'Yongam Community Welfare Center' announced on the 7th that Nepes delivered 280 Lunar New Year gift sets to local underprivileged households.This gift set, which consists of multigrain rice, two types of nuts, gamjatang, meat stew, and sweet persimmons, was produced by Nepes employees over a period of six days from the 1st to the 6th.Nepes and World Vision Yongam Community Welfare Center executives and staff delivered gift sets to vulnerable groups at risk of skipping meals, including 100 households in Cheongan-myeon and 180 low-income senior households using welfare centers.An official from Nepes said, “We hope that some warmth will be delivered to those in need in the community,” and added, “We will continue to work together to create a compassionate community.”https://www.inews365.com/news/article.html?no=801015

2024-02-08

-

-

Nepes Team Leader Gil Ho-seop Wins Commendation from the Minister of Environment

Team leader Gil Ho-seop of (Nepes Environmental Safety Team of Semiconductor Division) received a citation from the Minister of Environment in recognition of his contribution to environmental conservation.Nepes received the award in recognition of its environmental and chemical preventive management activities and activities related to regional environmental conservation at a commendation ceremony organized by the Ministry of Environment on December 29, 2023.As for the main activities, ▲Reducing waste material resources and greenhouse gases and reducing fixed costs (1.9bn) ▲Removal of high-concentration nitrogen and non-degradable organic matter from the semiconductor production process through the Clean Factory technology development project (the Ministry of Industry and Commerce) ▲Companies near Ochang Industrial Complex, Chemical Safety Community of Small and Medium Enterprises, Chungbuk Technical Association (Executive Activities) and Chungcheongbuk-do Environmental Technology Advisory ▲23 years Environmental and chemical related government offices unannounced inspection 5 times Unsuitable 0 cases ▲22 years ESG evaluation excellent grade A maintenance.We will make more efforts to preserve the environment that matches the status of Korea's only high-tech post-processing company, said team leader Gil Ho-seop. "We will also prepare more solidly for major environmental and safety issues regarding the business division's key promotion items in 24 years."

2024-01-12

-

-

Nepes was selected as a best-case company for safety and health management.

Nepes was selected as the best company in the announcement of best practices of the Electronic Industry Safety and Health Council hosted by the Korea Occupational Safety and Health Agency's Smart Safety and Health Institute.To prevent poisoning accidents caused by major substances handled by the electronics industry, the Smart Safety and Health Research Institute has formed a consortium composed of experts related to the electronics industry, main contractors, and suppliers, and has been actively reflecting opinions through policy gathering. In September, we shared best practices in safety and health management.Nepes was awarded the Grand Prize for outstanding achievements among the announced companies.Since 2021, Nepass has implemented a company-wide safety and health management evaluation system to comply with safety and health regulations and achieve disaster-free goals, and is essential to all employees' KPIs to raise awareness of safety and health, and is checking risks at manufacturing sites through the "SEMI-WEB Safety Inspection Program" introduced in 2017. In addition, it is striving to create a healthy working environment by operating internal and external psychological counseling programs, invited lectures, and job stress prevention education.Gil Ho-seop, head of the Environmental Safety Team, said, "Thanks to the safety and health management activities being carried out in collaboration with other departments, it seems to have been a meaningful year for Nepass to be recognized as an excellent company by external organizations." "In the upcoming new year, rather than being satisfied with the present, we will gather wisdom with our department members to make more efforts to become a Nepass that can sustain healthy production with more safety and health activities."

2023-12-22

-

-

Nepes hosts special lecture on author of 'WOORIMAL(Korean) Vitamin'

Nepes held a special lecture on the author for executives and staff members at the Cheongju 2 Campus Atrium on the 14th.This lecture was held in commemoration of Nepes' re-certification of '2023 Korea Reading Management Excellent Workplace', and the author of 'WOORIMAL(Korean) Vitamin' and the representative of Korean Culture Association Jung Jae Hwan gave a lecture.Jung Jae-hwan talked about the background of starting the Hangul Movement and the changed life afterward and talked about the importance and greatness of Korean. In addition, he conveyed the message of the book, "Words have the power to hold the identity of the speaker," and advised him to avoid negative language habits such as excessive use of foreign words and wrong spelling in his work life.One staff said, "I felt that Hangul is our asset and pride to be cherished. It was a meaningful lecture to re-engrave the importance of Korean."The ‘Reading Management Excellent Workplace’ certification system is a system hosted by the Ministry of Culture, Sports and Tourism and organized by Korea Management Association Consulting (KMAC) to select organizations that have made efforts to promote a reading culture in the workplace. Since 2006, Nepes has been striving for the mutual growth of individuals and organizations in a culture of reading, sharing, questioning, and discussing books through its reading management program, 'i Training', and has been certified as an 'excellent workplace for reading management' for seven consecutive years since 2017.

2023-12-14

-

-

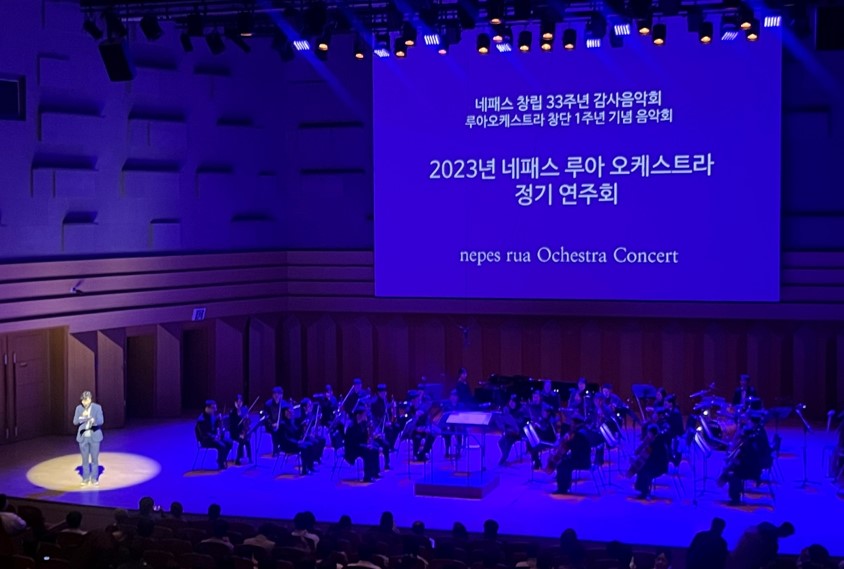

Nepes Rua Orchestra Hosts "33rd Anniversary of Nepes Founding / 1st Anniversary of Rua Orchestr

The Nepes Rua Orchestra held the "33rd Anniversary of Nepes Founding / 1st Anniversary of Rua Orchestra Inception Thanksgiving Concert" at Cheongju Art Center on the 20th.This performance, commemorating the 33rd anniversary of Nepes' establishment and the 1st anniversary of the Rua Orchestra's inception, was attended by about 420 individuals, including Nepes employees/families, faculty members of special education schools in the Cheongju area, and relevant members of disabled groups in the Chungbuk region. Together, they witnessed a moving performance.Under the passionate baton of conductor Nam-Jin Kim, the first act, themed 'Vocation' covered repertoire such as Mozart's 'Papageno Suite,' Brevval's 'Concerto no.1 F major 1st movement,' and Herbert's 'Italian Street Song.' The subsequent acts were themed 'Passion' for the second act, 'Faith' for the third, and 'Dream' for the fourth. The performances by Rua Orchestra members and Nepes music class instructors colored the hall with emotion and hope.Nepes Chairman Byung-Koo Lee, in his message of gratitude, conveyed, "I'm truly delighted and grateful to have this thanksgiving concert on the occasion of the 1st anniversary of the Rua Orchestra's inception." He further added, "I'd like to express my gratitude to Artistic Director Nam-Jin Kim, the guiding teachers, government officials, and all the sponsors who have generously supported us, allowing us to grow to a national scale within just a year."

2023-10-23