Nepes, which eliminated semiconductor

leadframe, ‚Äúsemiconductor packaging efficiency 10 times‚Ķ Achieved 1 trillion won in sales within 3 years‚ÄĚ

Semiconductor manufacturing is divided

into a ‚Äėpre-process‚Äô, in which

a circuit is engraved on thin silicon to manufacture a chip, and a ‚Äėpost-process‚Äô, in which the manufactured

chip is packaged (packaging) using a substrate and metal wire.

Nepes a company specializing in

semiconductor backend-processing, recently started produce the 'Fan-out panel

level packaing'(FOPLP) that packaged high-performance semiconductors with a

thickness of 0.9nm and works in the form of a square panel(600mm)

It is the only technology in the world

that increases the net die (the number of chips per wafer or panel) more than

tenfold from 1,000 to 10,000. Since there is no wasted area on the edge of the

circular wafer, productivity is also greatly improved. Lee Byung-koo

(pictured), chairman of Nepes, said, “We are pushing

the semiconductor packaging technology to the limit through FOPLP and

others."

Nepes, a listed company on the KOSDAQ, is

a cutting-edge company in the packaging field. They mainly receive chips from

Samsung Electronics, etc., and package them to complete semiconductors. It has

the capacity to process 1104,000 wafers per year. Sales are 65% export and 35%

domastic. Last year, it recorded 418.4 billion won in sales and 16.4 billion

won in operating loss.

Nepes has been developing a technology

for packaging chips to be light, thin and short (light, thin, short and small)

so that semiconductors can be put into smartphones and IoTs. In the past,

semiconductors were shaped like a black centipede. Its size was much larger

than the chip. This is because the chip was placed on the board, a connection

part similar to a centipede was made using a copper wire, etc., and then an

epoxy resin was placed on it to fix it. Due to its complex structure, the heat

problem was also serious.

In contrast, the semiconductors packaged

by Nepes do not change significantly in the size of a square chip. This is

because they developed 'Wafer Level Packaging (WLP)' technology in the 2000s,

which coats a thin metal film just below the chip, prints a circuit diagram

with a laser, and sends and receives electrical signals using fine metal

protrusions. The thickness of the finished semiconductor was only 0.4 nm.

Overseas semiconductor manufacturers that have recognized Nepes' technology have

sent their chips by air to request packaging.

Nepes, which eliminated semiconductor

centipedes, “semiconductor packaging efficiency 10

times‚Ķ Achieved 1 trillion won in sales within 3 years‚ÄĚ

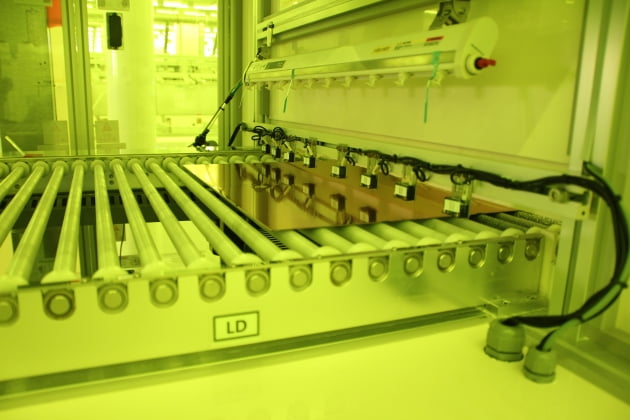

Nepes spares no expense in R&D and

facility investment to maintain cutting-edge technology. Last year, an

additional 42,962„é° factory site was prepared in Goesan,

North Chungcheong Province, and advanced packaging facilities such as WLP and

FOPLP were installed. Last year's operating loss is related to such facility investment.

Nepes'

earnings are expected to improve significantly this year. This is because the

total production capacity will increase by about 60% when the FOPLP facility

starts operation. The securities industry predicts that Nepes will record 606

billion won in sales and 52 billion won in operating profit this year. This is

almost twice as much sales as in 2020 (343.6 billion won).