Leading

advanced packaging company Nepes Laweh

continues its innovation in advanced package technology, following the 600mm

FOPLP (Fan-out Panel Level Package).

Nepes

Laweh

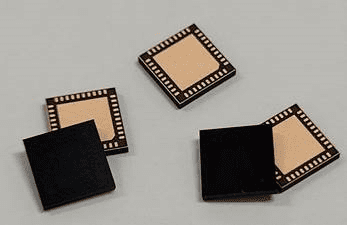

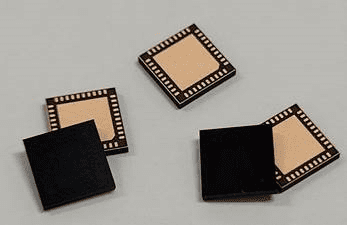

announced that they have, for the first time in the world, implemented FOPLP

solely through the Molding technique, without using the expensive Polyimide

(PI), which is an essential material in the fan-out process.

▲Implementation of FO-PLP using PI alternative packaging technology(Photo=Nepes)

Based

on Deca

Technologies' M-Series™, this technology has been commercialized for the first

time in the world by Nepes Laweh, and they have recently initiated

product supplies to analog and automotive semiconductor company in the United

States.

This

technology, which does not use PI, not only simplifies the process and improves

productivity, but also has the potential to enhance product reliability. It is

expected that this technology can extensively replace traditional conventional

molding packages, such as QFN.

In

particular, analog semiconductor manufacturers, who frequently need to change

and develop various products, can reduce the supply risk of materials like PCBs

and lead frames. Additionally, it is a strong advantage that this technology

allows for the transition to the fan-out process while maintaining existing

semiconductor specifications, thus reducing the burden of new certifications

for customers.

Especially

for products with large production volumes and stringent front-end customer

certifications, such as automotive Microcontroller Units (MCU), the company

expects this technology to offer advantages in manufacturing and quality

control.

A

Nepes official conveyed, “The commercialization of fan-out molding technology

is expected to further strengthen our technological competitiveness in the

advanced package market.”

Nepes

Laweh

has strategized to expand its customer base by applying fan-out PLP technology

to various application products, including industrial and automotive products,

starting with the supply of analog semiconductor samples.